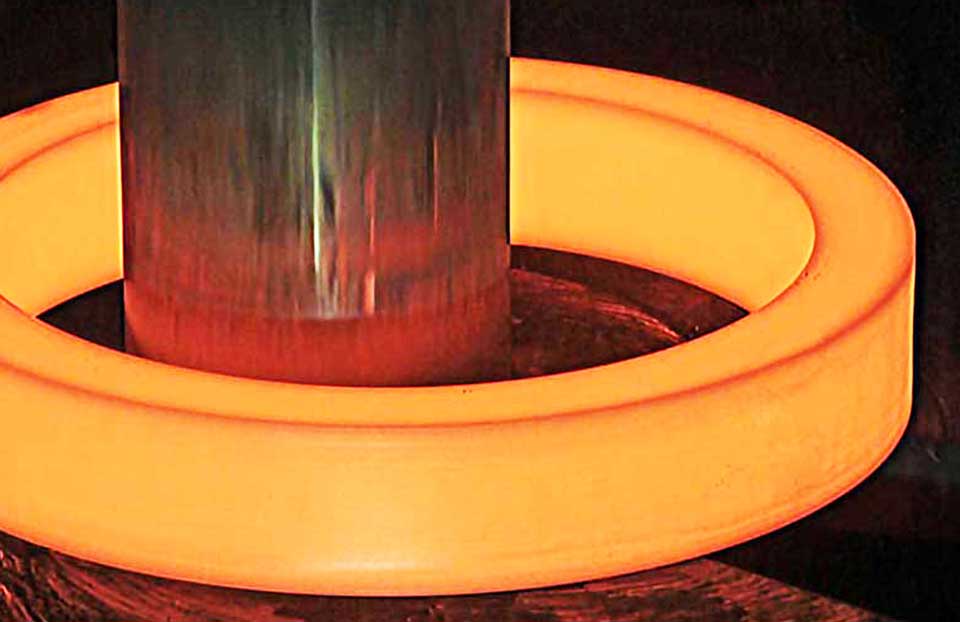

Quality Control Systems

To ensure high-quality manufacturing, AKA’s quality control mechanism evaluates soundness of the manufacturing processes and quality of the materials throughout the entire production line.

In order to maintain high quality of the products, raw material is tested in labs, then, all the processes such as cutting, rolling, welding, lathing, drilling, sandblasting, painting and dimension measurements are precisely inspected by the quality control department.

Welding is done by skilled, experienced and licensed employees under proper supervision and UT test is carried out on the parts at different stages.

The parts are also checked by hydrostatic tests forcing up to one and a half times of their designed nominal pressure tolerance to ensure their strength and durability.

Whenever needed, UTS (Ultimate tensile strength) test is performed and heat treatment is done on the parts that are subject to stress as they are tabulated for steel and steel alloys.

Final quality control of each stage is required as the prerequisite of the next stage. This process continues throughout the whole production line to loading platform and shipping containers.

Standards

AKA products are manufactured in accordance with world-class standards such as DIN, ISO BS, ANSI, AWWA, ASTM. If the client needs us to apply another specific standard, as long as there are no technical issues, we will adjust the production to it.