Coupling

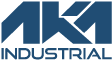

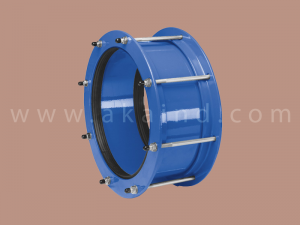

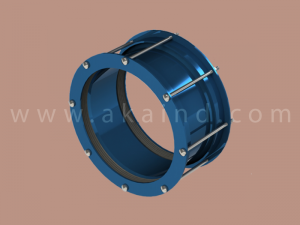

AKA Industrial Group, as the first and only manufacturer of couplings in Iran and the Middle East, produces all kinds of epoxy-coated couplings for pipes of different materials and various outer diameters from 350 mm up to 3000 mm. Couplings are used for joining pipes of the same or different materials with the same outer diameter. Stepped Couplings are used to connect pipes with different outer diameters and pipes of different materials.

Main Advantages of Using AKA Couplings

The most important feature of AKA couplings is the ease and speed in piping operations that effectively decreases project costs by reducing project duration. Besides fast assembling, an AKA Coupling, when used throughout a pipeline, will easily take care of expansion and contraction, limited ground movement and long radius curves.

Sealing Ring

Exclusive AKA sealing rings molded in AKA’s plant meet the exact specifications and assure perfect lifetime sealing while fulfilling all the relevant British standards.

Coupling

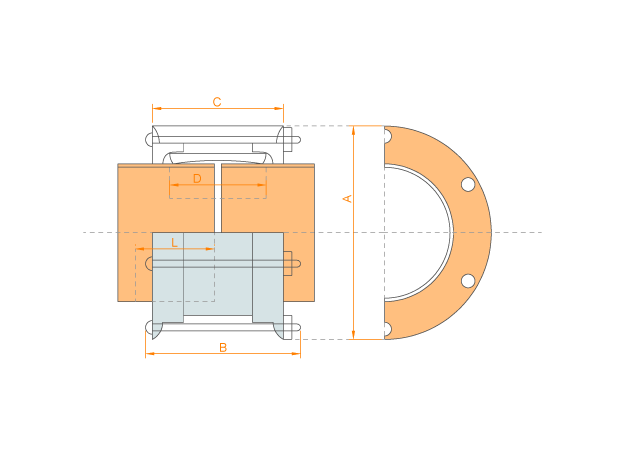

| PIPE DIMENSIONS | COUPLING DIMENSION AND WEIGHT | ||||||||||

| Nom Bore | Pipe O.D. | Tolerance on O.D. for Distance L |

L Min. | A | B | C | D × average Thickness | Bolts No. Dia × Length |

Max. Test Pressure (atm) lb/in2 |

Approx Weight (kg) |

Stud No. |

| 350 | 356 14 |

± 1.6 | 152 | 460 | 254 | 216 | 178 × 8 | 6, 16 × 24 | 44 650 |

30 | 2 |

| 350 | 356 14 |

± 1.6 | 152 | 470 | 260 | 229 | 178 × 10 | 10, 16 × 25 | 58 850 |

32 | 2 |

| 400 | 406 16 |

± 1.6 | 152 | 511 | 254 | 216 | 178 × 8 | 6, 16 × 24 | 41 600 |

34 | 2 |

| 400 | 406 16 |

± 1.6 | 152 | 521 | 260 | 229 | 178 × 10 | 12, 16 × 25 | 54 800 |

37 | 3 |

| 400 | 419 16.5 |

± 1.6 | 152 | 524 | 254 | 216 | 178 × 8 | 8, 16 × 24 | 41 600 |

34 | 3 |

| 450 | 457 18 |

± 1.6 | 152 | 562 | 254 | 216 | 178 × 8 | 8, 16 × 24 | 37 550 |

39 | 3 |

| 450 | 457 18 |

± 1.6 | 152 | 572 | 260 | 229 | 178 × 10 | 12, 16 × 25 | 51 750 |

42 | 3 |

| 500 | 508 20 |

± 1.6 | 152 | 613 | 254 | 216 | 178 × 8 | 10, 16 × 24 | 34 500 |

44 | 3 |

| 500 | 508 20 |

± 1.6 | 152 | 622 | 260 | 229 | 178 × 10 | 12, 16 × 25 | 51 750 |

47 | 3 |

| 500 | 508 20 |

± 1.6 | 152 | 638 | 286 | 238 | 178 × 12 | 14, 16 × 27 | 58.5 860 |

55 | 3 |

| 550 | 559 22 |

± 1.6 | 152 | 664 | 254 | 216 | 178 × 8 | 10, 16 × 24 | 32 480 |

49 | 3 |

| 550 | 559 22 |

± 1.6 | 152 | 673 | 260 | 229 | 178 × 10 | 12, 16 × 25 | 51 750 |

52 | 3 |

| 550 | 559 22 |

± 1.6 | 152 | 689 | 286 | 238 | 178 × 12 | 14, 16 × 27 | 55 808 |

60 | 3 |

| 600 | 610 24 |

± 1.6 | 152 | 714 | 254 | 216 | 178 × 8 | 10, 16 × 24 | 27 400 |

54 | 3 |

| 600 | 610 24 |

± 1.6 | 152 | 724 | 260 | 229 | 178 × 10 | 12, 16 × 25 | 41 600 |

58 | 3 |

| 600 | 610 24 |

± 1.6 | 152 | 740 | 286 | 238 | 178 × 12 | 14, 16 × 27 | 48 705 |

66 | 3 |

| 650 | 660 26 |

± 1.6 | 152 | 765 | 254 | 216 | 178 × 8 | 10, 16 × 24 | 26.2 385 |

60 | 3 |

| 650 | 660 26 |

± 1.6 | 152 | 775 | 260 | 229 | 178 × 10 | 12, 16 × 25 | 41 600 |

64 | 3 |

| Unit: mm | |||||||||||

| PIPE DIMENSIONS | COUPLING DIMENSION AND WEIGHT | ||||||||||

| Nom Bore | Pipe O.D. | Tolerance on O.D. for Distance L |

L Min. | A | B | C | D × average Thickness | Bolts No. Dia × Length |

Max. Test Pressure (atm) lb/in2 |

Approx Weight (kg) |

Stud No. |

| 650 | 660 26 |

± 1.6 | 152 | 791 | 286 | 238 | 178 × 12 | 16, 16 × 27 | 47 690 |

72 | 3 |

| 700 | 711 28 |

± 1.6 | 152 | 816 | 254 | 216 | 178 × 8 | 10, 16 × 24 | 24.5 360 |

65 | 3 |

| 700 | 711 28 |

± 1.6 | 152 | 826 | 260 | 229 | 178 × 10 | 12, 16 × 25 | 41 660 |

69 | 3 |

| 700 | 711 28 |

± 1.6 | 152 | 841 | 286 | 238 | 178 × 12 | 16, 16 × 27 | 45 660 |

77 | 3 |

| 750 | 762 30 |

± 1.6 | 152 | 876 | 260 | 229 | 178 × 10 | 14, 16 × 25 | 39.5 580 |

74 | 3 |

| 750 | 762 30 |

± 1.6 | 152 | 892 | 286 | 238 | 178 × 12 | 18, 16 × 27 | 42 620 |

83 | 3 |

| 800 | 813 32 |

± 1.6 | 152 | 927 | 260 | 229 | 178 × 10 | 14, 16 × 25 | 32 470 |

79 | 3 |

| 800 | 813 32 |

± 1.6 | 152 | 943 | 286 | 238 | 178 × 12 | 18, 16 × 27 | 41 600 |

89 | 3 |

| 850 | 864 34 |

± 1.6 | 152 | 978 | 260 | 229 | 178 × 10 | 14, 16 × 25 | 30 440 |

84 | 3 |

| 850 | 864 34 |

± 1.6 | 152 | 994 | 286 | 238 | 178 × 12 | 18, 16 × 27 | 38 560 |

95 | 3 |

| 900 | 914 36 |

± 1.6 | 152 | 1029 | 260 | 229 | 178 × 10 | 14, 16 × 25 | 27 400 |

89 | 3 |

| 900 | 914 36 |

± 1.6 | 152 | 1045 | 286 | 238 | 178 × 12 | 18, 16 × 27 | 30 440 |

101 | 3 |

| 1000 | 1016 40 |

± 1.6 | 152 | 1130 | 260 | 229 | 178 × 12 | 18, 16 × 27 | 24.5 360 |

109 | 3 |

| 1000 | 1016 40 |

± 1.6 | 152 | 1146 | 286 | 238 | 178 × 14 | 26, 16 × 27 | 34 500 |

130 | 3 |

| 1050 | 1067 42 |

± 1.6 | 152 | 1181 | 260 | 229 | 178 × 12 | 18, 16 × 25 | 24.4 300 |

112 | 3 |

| 1050 | 1067 42 |

± 1.6 | 152 | 1197 | 286 | 238 | 178 × 14 | 20, 16 × 27 | 30.6 450 |

132 | 3 |

| 1100 | 1118 44 |

± 1.6 | 152 | 1232 | 260 | 229 | 178 × 12 | 18, 16 × 25 | 20.4 300 |

118 | 3 |

| 1100 | 1118 44 |

± 1.6 | 152 | 1248 | 286 | 233 | 178 × 14 | 20, 16 × 27 | 30.6 450 |

140 | 3 |

| 1200 | 1219 48 |

± 1.6 | 152 | 1333 | 260 | 229 | 178 × 12 | 18, 16 × 25 | 18.4 270 |

132 | 3 |

| 1200 | 1219 48 |

± 1.6 | 152 | 1349 | 286 | 238 | 178 × 14 | 20, 16 × 27 | 23.8 350 |

165 | 3 |

| 1400 | 1420 55.906 |

± 1.6 | 152 | 1549 | 286 | 238 | 178 × 14 | 24, 16 × 27 | 23.8 350 |

186 | 3 |

| 1600 | 1620 63.780 |

± 3.2 | 152 | 1751 | 286 | 238 | 178 × 14 | 24, 16 × 27 | 21.8 320 |

236 | 3 |

| 1800 | 1820 71.654 |

± 3.2 | 152 | 1951 | 286 | 238 | 178 × 14 | 32, 16 × 27 | 19.1 280 |

265 | 3 |

| 2000 | 2020 79.528 |

± 3.2 | 191 | 2151 | 362 | 314 | 254 × 14 | 36, 16 × 35 | 16.3 240 |

294 | 3 |

| 2100 | 2138 84 |

± 3.2 | 191 | 2265 | 362 | 314 | 254 × 14 | 36, 16 × 35 | 13.6 200 |

309 | 3 |

| Unit: mm | |||||||||||

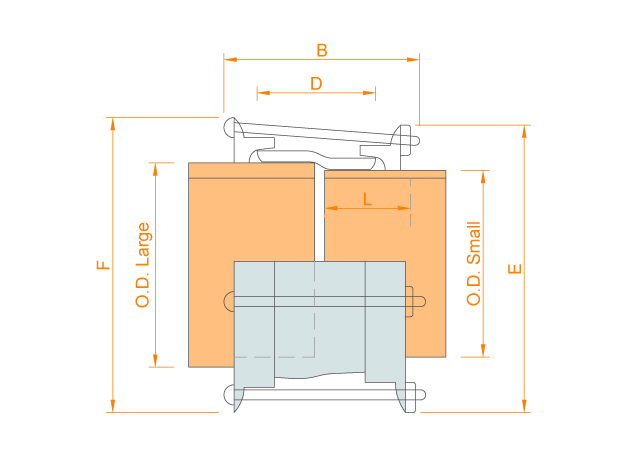

Stepped Coupling

| Nom. | Bore | Pipe O.D | Tolerance on O.D | Coupling Details | ||||||||||

| Steel | Ductile Iron | Steel | Ductil Iron | Steel | Ductile Iron | L | B | D × Average Thickness | E Dia | F Dia | No. of Bolts | Dia × Length | Test Pressure (atm) |

Approx Weight (kg) |

| 350 | 350 | 356 14 |

378 | ± 1.6 | + 2.7 - 3.5 |

125 | 254 | 178 × 8 | 460 | 482 | 8 | 16 × 24 | 40 | 30 |

| 400 | 400 | 406 16 |

429 | ± 1.6 | + 2.8 - 4.0 |

125 | 254 | 178 × 8 | 511 | 534 | 8 | 16 × 24 | 37 | 34 |

| 450 | 450 | 457 57 |

480 | ± 1.6 | + 2.9 - 4.0 |

125 | 254 | 178 × 8 | 562 | 585 | 8 | 16 × 24 | 34 | 40 |

| 500 | 500 | 508 20 |

532 | ± 1.6 | + 3.0 - 4.0 |

125 | 254 | 178 × 8 | 613 | 637 | 10 | 16 × 24 | 33 | 45 |

| 600 | 600 | 610 24 |

635 | ± 1.6 | + 3.2 - 4.5 |

125 | 254 | 178 × 8 | 714 | 739 | 12 | 16 × 24 | 25 | 55 |

| 700 | 700 | 711 28 |

738 | ± 1.6 | + 3.4 - 4.5 |

125 | 254 | 178 × 8 | 816 | 843 | 12 | 16 × 24 | 24 | 67 |

| 800 | 800 | 813 32 |

842 | ± 1.6 | + 1.0 - 4.5 |

125 | 260 | 178 × 10 | 927 | 956 | 14 | 16 × 25 | 28 | 82 |

| 900 | 900 | 914 36 |

945 | ± 1.6 | + 1.0 - 5.0 |

150 | 260 | 178 × 10 | 1029 | 1060 | 14 | 16 × 25 | 23 | 93 |

| 1000 | 1000 | 1016 40 |

1048 | ± 1.6 | + 1.0 - 5.0 |

150 | 260 | 178 × 12 | 1130 | 1162 | 14 | 16 × 25 | 21 | 114 |

| 1100 | 1100 | 1118 44 |

1152 | ± 1.6 | + 1.0 - 6.0 |

150 | 260 | 178 × 12 | 1232 | 1266 | 16 | 16 × 25 | 19 | 122 |

| 1200 | 1200 | 1219 48 |

1255 | ± 1.6 | + 1.0 - 6.0 |

200 | 260 | 178 × 12 | 1333 | 1369 | 18 | 16 × 25 | 18 | 43 |

| 1400 | 1400 | 1420 55.90 |

1462 | ± 3.2 | + 1.0 - 7.0 |

200 | 286 | 178 × 14 | 1549 | 1591 | 20 | 16 × 27 | 21 | 192 |

| 1600 | 1600 | 1620 63.78 |

1668 | ± 3.2 | + 1.0 - 7.0 |

200 | 286 | 178 × 14 | 1751 | 1799 | 24 | 16 × 27 | 20 | 242 |

| 1800 | 1800 | 1820 71.65 |

1875 | ± 3.2 | + 1.0 - 8.0 |

200 | 286 | 178 × 14 | 1951 | 2006 | 32 | 16 × 27 | 18 | 274 |

| 2000 | 2000 | 2020 79.53 |

2082 | ± 3.2 | + 1.0 - 8.0 |

200 | 362 | 178 × 14 | 2151 | 2213 | 36 | 16 × 35 | 16 | 304 |

| Unit: mm | ||||||||||||||